Page 241 - floMAX Catalogue 2016

P. 241

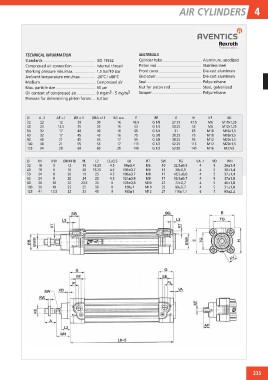

AIR CYLINDERS 4

TECHNICAL INFORMATION MATERIALS

Standards

Compressed air connection ISO 15552 Cylinder tube Aluminum, anodized

Working pressure min./max. Internal thread

Ambient temperature min./max. 1.5 bar/10 bar Piston rod Stainless steel

Medium -20°C / +80°C

Max. particle size Compressed air Front cover Die-cast aluminum

Oil content of compressed air 50 µm

Pressure for determining piston forces 0 mg/m3 - 5 mg/m3 End cover Die-cast aluminum

6,3 bar

Seal Polyurethane

Nut for piston rod Steel, galvanized

Scraper Polyurethane

Ø A -2 AF +1 ØB d11 ØBA d11 BG min. E EE G H KF KK

32 22 12 30 30 16 46.5 G 1/8 27.75

40 24 13.5 35 35 16 53 G 1/4 33.25 47.5 M6 M10x1,25

50 32 17 40 40 16 65 G 1/4

63 32 17 45 45 16 75 G 3/8 31 53 M8 M12x1,25

80 40 21 45 45 17 95 G 3/8 38.25

100 40 21 55 55 17 115 G 1/2 38.25 65 M10 M16x1,5

125 54 28 60 60 20 140 G 1/2 42.25

53.85 75 M10 M16x1,5

95 M12 M20x1,5

115 M12 M20x1,5

140 M16 M27x2

Ø KV KW ØMM f8 PL L2 L3±0,5 L8 RT SW TG VA -1 VD WH

32 16 5 12 16 16.25 4.5 94±0,4 M6 10 32,5±0,5 4 5 26±1,4

40 18 6 16 20 18.25 4.5 105±0,7 M6 13 38±0,5 4 5 30±1,4

50 24 8 20 19 25 4.5 106±0,7 M8 17 46,5±0,6 4 5 37±1,4

63 24 8 20 24 25 4.5 121±0,8 M8 17 56,5±0,7 4 5 37±1,8

80 30 10 25 23.5 33 0 128±0,8 M10 22 72±0,7 4 5 46±1,8

100 30 10 25 25 36 0 138±1 M10 22 89±0,7 4 5 51±1,8

125 41 13.5 32 33 45 0 160±1 M12 27 110±1,1 6 7 65±2,2

235