Page 218 - floMAX Catalogue 2016

P. 218

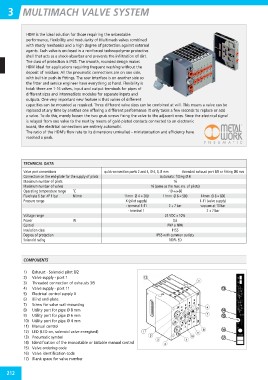

3 MULTIMACH VALVE SYSTEM

HDM is the ideal solution for those requiring the unbeatable

performance, flexibility and modularity of Multimach valves combined

with sturdy mechanics and a high degree of protection against external

agents. Each valve is enclosed in a reinforced technopolymer protective

shell that acts as a shock-absorber and prevents the infiltration of dirt.

The class of protection is IP65. The smooth, rounded design makes

HDM ideal for applications requiring frequent washing without the

deposit of residues. All the pneumatic connections are on one side,

with built-in push-in fittings. The user interface is on another side so

the fitter and service engineer have everything at hand. Flexibility is

total: there are 1-16 valves, input and output terminals for pipes of

different sizes and intermediate modules for separate inputs and

outputs. One very important new feature is that valves of different

capacities can be mounted as required. Three different valve sizes can be combined at will. This means a valve can be

replaced at any time by another one offering a different performance. It only takes a few seconds to replace or add

a valve. To do this, merely loosen the two grub screws fixing the valve to the adjacent ones. Since the electrical signal

is relayed from one valve to the next by means of gold-plated contacts connected to an electronic

board, the electrical connections are entirely automatic.

The ratio of the HDM’s flow rate to its dimensions unrivalled - miniaturisation and efficiency have

reached a peak.

TECHNICAL DATA

Valve port connections quick-connection ports 2 and 4, Ø 4, 6, 8 mm threaded exhaust port 3/8 or fitting Ø8 mm

Connection on the end-plate for the supply of pilots Automatic fitting Ø 4

Maximum number of pilots 16

Maximum number of valves 16 (same as the max. no. of pilots)

Operating temperature range ˚C -10 ÷≤+60

Fluid rate 6 bar ∆P 1 bar NI/min 11mm Ø 4 = 200 11mm Ø 6 = 500 14mm Ø 8 = 800

Pressure range X (pilot supply) 1-11 (valve supply)

- terminal 1-11 2 ÷ 7 bar vacuum at 10 bar

- terminal 1 2 ÷ 7 bar

Voltage range 24 VDC ± 10%

Power W 0,6

Control PNP o NPN

Insulation class F155

Degree of protection IP65 with common outlets

Solenoid rating 100% ED

COMPONENTS

1) Exhaust - Solenoid pilot 8/2

2) Valve supply - port 1

3) Threaded connection of exhausts 3/5

4) Valve supply - port 11

5) Electrical control supply X

6) Blind end-plate

7) Screw for valve wall-mounting

8) Utility port for pipe Ø 8 mm

9) Utility port for pipe Ø 6 mm

10) Utility port for pipe Ø 4 mm

11) Manual control

12) LED (LED on, solenoid valve energised)

13) Pneumatic symbol

14) Identification of the monostable or bistable manual control

15) Valve ordering code

16) Valve identification code

17) Blank space for valve number

212