Page 183 - floMAX Catalogue 2016

P. 183

HYDRAULIC TANK ACCESSORIES 2

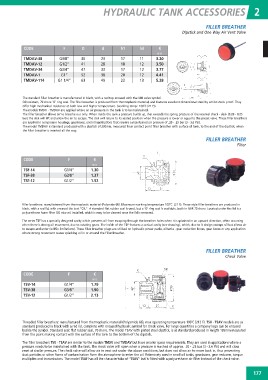

FILLER BREATHER

Dipstick and One Way Air Vent Valve

CODE F D d h1 h3 €

N16

TMDAV-38 G3/8” 36 23 17 11 3.20

TMDAV-12 G1/2” 41 28 18 12 3.50

TMDAV-34 G3/4” 47 33 17 12 3.77

TMDAV-1 G1” 52 38 20 12 4.41

TMDAV-114 G1 1/4” 63 49 23 13 5.28

The standard filler breather is manufactured in black, with a red top encased with the UNI valve symbol.

Oil resistant, 70 shore ‘O’ ring seal. The filler breather is produced from thermoplastic material, and features excellent dimensional stability whilst shock proof. They

offer high mechanical resistance at both low and higher temperature. (working temp.: 100˚C (21 F)).

The models TMDV - TMDAV are applied where an air pressure in the tank is to be maintained.

The filler breather allows air to breathe out only. When inside the tank a pressure builds up, that exceeds the spring pressure of the internal check - desk (0.20 - 0.25

bar) the disk will lift and allow the air to escape. The disk will return to its seated position when the pressure is lower or equal to the preset valve. These filler breathers

are applied in compressor housings, gearboxes, and all applications that require a maintained air pressure of .20 - .25 bar (3 - 3.6 PSI).

The model TMDAV is standard produced with a dipstick of 200mm, measured from contact point filler breather with surface of tank, to the end of the dipstick, when

the filler breather is inserted all the way.

FILLER BREATHER

Filter

CODE F €

N16

TSF-14 G1/4” 1.30

TSF-38 G3/8” 1.37

TSF-12 G1/2” 1.52

Filler breathers: manufactured from thermoplastic material (Polymide 66). Maximum working temperature 100˚C (21 F). These style filler breathers are produced in

black, with a red lid, with encased the text “OIL”. A standard flat rubber seal is used, but a ‘O’ ring seal is available, both in NBR 70 shore. Located under the lid is a

polyurethane foam filter (50 micron) installed, which is easy to be cleaned once the lid is removed.

The series TSF has a specially designed cavity which prevents oil from escaping through the breather holes when it is splashed in an upward direction, often occurring

when there is strong oil movement, due to rotating gears. The inside of the TSF features a conical cavity (see drawing), which, due to it design entraps oil but allows air

to escape and enter (within limitations). These filler breather plugs are utilised on hydraulic power packs, oiltanks , gear reduction boxes, gear boxes or any application

where strong movement causes splashing oil in or around the Filler Breather.

FILLER BREATHER

Check Valve

CODE F €

N16

TSV-14 G1/4” 1.79

TSV-38 G3/8” 1.90

TSV-12 G1/2” 2.13

Threaded filler breathers: manufactured from thermoplastic material (Polyamide 66), max operating temperature 100˚C (212 F). TSV - TSAV models are as

standard produced in black with a red lid, complete with encased hydraulic symbol for check valve. For large quantities a company logo can be encased

beside the symbol. Standard seal: flat rubber seal, 70 shore. The model TSAV with plated steel dipstick, is as standard produced in length 195mm measured

from the point making contact with the surface of the tank to the bottom of the dipstick.

The filler breathers TSV - TSAV are similar to the models TMDV and TMDAV but have smaller space requirements. They are used in applications where a

pressure needs to be maintained with the tank. The check valve will open when a pressure is reached of approx. .20 - .25 bar (3 - 3.6 PSI) and will close

reset at similar pressure. The check valve will allow air to vent out under the above conditions, but does not allow air to move back in, thus preventing

dust particles or other forms of contamination form the atmosphere to enter the oil. Extensively used in small oil tanks, gearboxes, gear reducers, torque

multiplies and transmissions. The model TSAF has all the characteristics of “TSAV” but is fitted with a polyurethane air filter instead of the check valve.

177