Page 233 - floMAX Catalogue 2016

P. 233

AIR KNIVES AND AMPLIFIERS 3

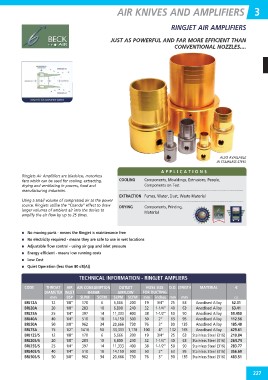

RINGJET AIR AMPLIFIERS

JUST AS POWERFUL AND FAR MORE EFFICIENT THAN

CONVENTIONAL NOZZLES....

ALSO AVAILABLE

IN STAINLESS STEEL

Ringjets Air Amplifiers are bladeless, motorless COOLING APPLICATIONS

fans which can be used for cooling, extracting,

drying and ventilating in process, food and Components, Mouldings, Extrusions, People,

manufacturing industries. Components on Test

Using a small volume of compressed air as the power EXTRACTION Fumes, Water, Dust, Waste Material

source, Ringjets utilise the “Coanda” effect to draw

larger volumes of ambient air into the device to DRYING Components, Printing,

amplify the air flow by up to 25 times.

Material

l No moving parts - means the Ringjet is maintenance free

l No electricity required - means they are safe to use in wet locations

l Adjustable flow control - using air gap and inlet pressure

l Energy efficient - means low running costs

l Low Cost

l Quiet Operation (less than 80 dB(A))

TECHNICAL INFORMATION - RINGJET AMPLIERS

CODE THROAT AIR AIR CO NSUMP TION OUTLET HOSE SIZ E O.D. LENGTH MATERIAL €

DIAMETER INLET @ 4BAR AIRFLOW FO R DUCT ING

mm BSP SLPM SCFM SLPM SCFM mm inches mm mm E26

BRJ12A 12 1/8” 170 6 5,666 200 19 3/4” 25 63 Anodised Alloy 52.31

63.41

BRJ20A 20 1/8” 283 10 6,800 240 32 1-1/4” 40 63 Anodised Alloy 59.450

112.56

BRJ25A 25 1/4” 397 14 11,333 400 38 1-1/2” 50 90 Anodised Alloy 185.48

429.61

BRJ40A 40 1/4” 510 18 14,150 500 50 2” 63 95 Anodised Alloy 210.84

264.74

BRJ50A 50 3/8” 962 34 20,666 730 76 3” 90 135 Anodised Alloy 283.77

356.69

BRJ75A 75 1/2” 1416 50 33,333 1,178 100 4” 132 165 Anodised Alloy 483.51

BRJ12S/S 12 1/8” 170 6 5,666 200 19 3/4” 25 63 Stainless Steel (316)

BRJ20S/S 20 1/8” 283 10 6,800 240 32 1-1/4” 40 63 Stainless Steel (316)

BRJ25S/S 25 1/4” 397 14 11,333 400 38 1-1/2” 50 90 Stainless Steel (316)

BRJ40S/S 40 1/4” 510 18 14,150 500 50 2” 63 95 Stainless Steel (316)

BRJ50S/S 50 3/8” 962 34 20,666 730 76 3” 90 135 Stainless Steel (316)

227