Page 234 - floMAX Catalogue 2016

P. 234

3 AIR KNIVES AND AMPLIFIERS

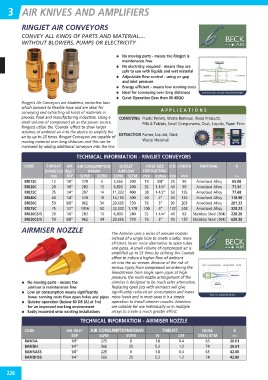

RINGJET AIR CONVEYORS

CONVEY ALL KINDS OF PARTS AND MATERIAL....

WITHOUT BLOWERS, PUMPS OR ELECTRICITY

l No moving parts - means the Ringjet is

maintenance free

l No electricity required - means they are

safe to use with liquids and wet material

l Adjustable flow control - using air gap

and inlet pressure

l Energy efficient - means low running costs

l Ideal for conveying over long distances

l Quiet Operation (less than 80 dB(A)

Ringjets Air Conveyors are bladeless, motorless fans

which connect to flexible hose and are ideal for APPLICATIONS

conveying and extracting all kinds of materials in

process, food and manufacturing industries. Using a CONVEYING Plastic Pellets, Waste Removal, Food Products,

small volume of compressed air as the power source, Pills & Tablets, Small Components, Dust, Liquids, Paper Trim

Ringjets utilise the ‘Coanda’ effect to draw larger

volumes of ambient air into the device to amplify the EXTRACTION Fumes, Liquids, Dust,

air by up to 25 times. Ringjet Conveyors are capable of Waste Material

moving material over long distances and this can be

increased by adding additional conveyors into the line.

TECHNICAL INFORMATION - RINGJET CONVEYORS

CODE THROAT AIR AIR CO NSUMP TION OUTLET HOSE SIZ E O.D. LENGTH MATERIAL €

DIAMETER INLET @ 4BAR AIRFLOW FO R DUCT ING

mm BSP SLPM SCFM SLPM SCFM mm inches mm mm E26

BRJ12C 12 1/8” 170 6 5,666 200 19 3/4” 25 95 Anodised Alloy 65.00

BRJ20C 20 1/8” 283 10 6,800 240 32 1-1/4” 40 95 Anodised Alloy 71.34

BRJ25C 25 1/4” 397 14 11,333 400 38 1-1/2” 50 135 Anodised Alloy 77.68

BRJ40C 40 1/4” 510 18 14,150 500 50 2” 63 135 Anodised Alloy 118.90

BRJ50C 50 3/8” 962 34 20,666 730 76 3” 90 203 Anodised Alloy 201.33

BRJ75C 75 1/2” 1416 50 33,333 1,178 100 4” 132 248 Anodised Alloy 320.23

BRJ20CS/S 20 1/8” 283 10 6,800 240 32 1-1/4” 40 63 Stainless Steel (304) 228.28

BRJ50CS/S 50 3/8” 962 34 20,666 730 76 3” 90 135 Stainless Steel (304) 629.36

AIRMISER NOZZLE The Airmiser uses a series of annular nozzles

instead of a single hole to create a safer, more

efficient, lower noise alternative to open tubes

and pipes. A small volume of compressed air is

amplified up to 25 times by utilising the Coanda

effect to induce a higher flow of ambient

air into the air stream. Because of the risk of

serious injury from compressed air entering the

bloodstream from single open pipes at high

pressure, the multi-nozzle arrangement of the

l No moving parts - means the airmiser is designed to be much safer alternative.

airmiser is maintenance free Replacing open jets with airmisers will give

l Low air consumption means significantly significantly reduced air consumption and lower

lower running costs than open holes and pipes noise levels and in most cases it is a simple

l Quieter operation (below 80 DB (A) at 1m) operation to install airmiser nozzles. Airmisers

for an improved working environment are suitable for use individually or in multiple

l Easily mounted onto existing installations arrays to create a much greater effect.

TECHNICAL INFORMATION - AIRMISER NOZZLE

CODE AIR INLET AIR CO NSUMPTI ON@5BAR T HRUST NOISE €

BAMSA BSP SLPM SCFM N LBF DB(A) @1M E26

BAMBH

BAMSASS 1/8” 225 8 1.8 0.4 65 20.61

BAMBHSS

1/4” 566 20 5.2 1.2 74 20.61

1/8” 225 8 1.8 0.4 65 42.80

1/4” 566 20 5.2 1.2 74 42.80

228